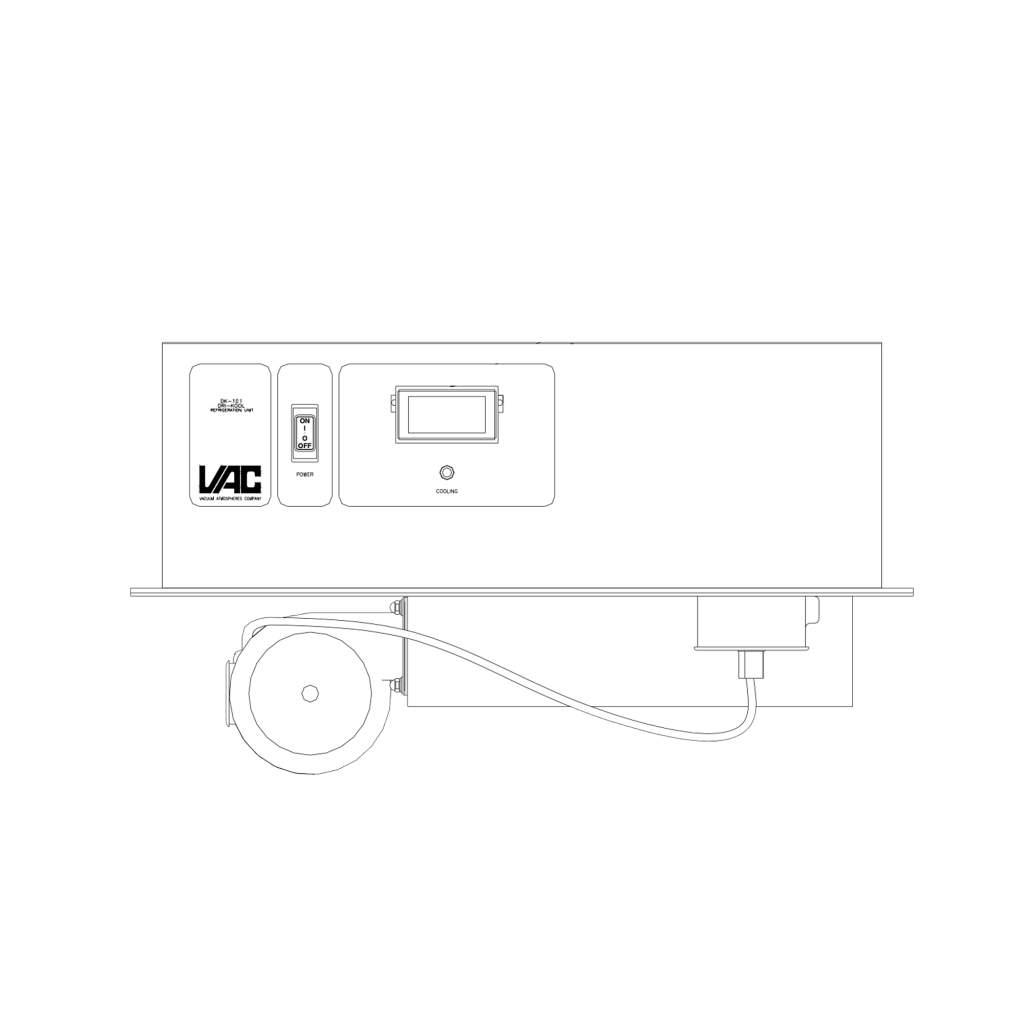

By removing heat produced as part of any internal glovebox processes, the system provides operator comfort and allows control of glovebox temperature, which may be an important process parameter.

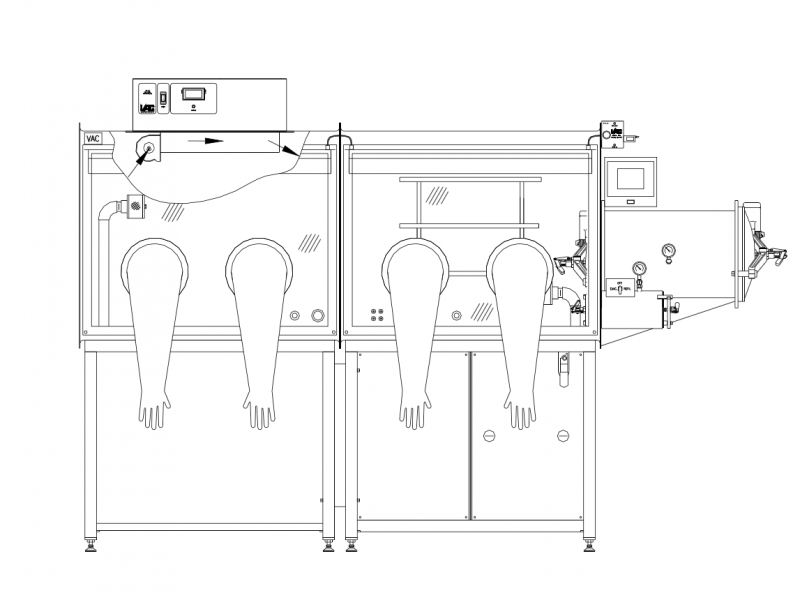

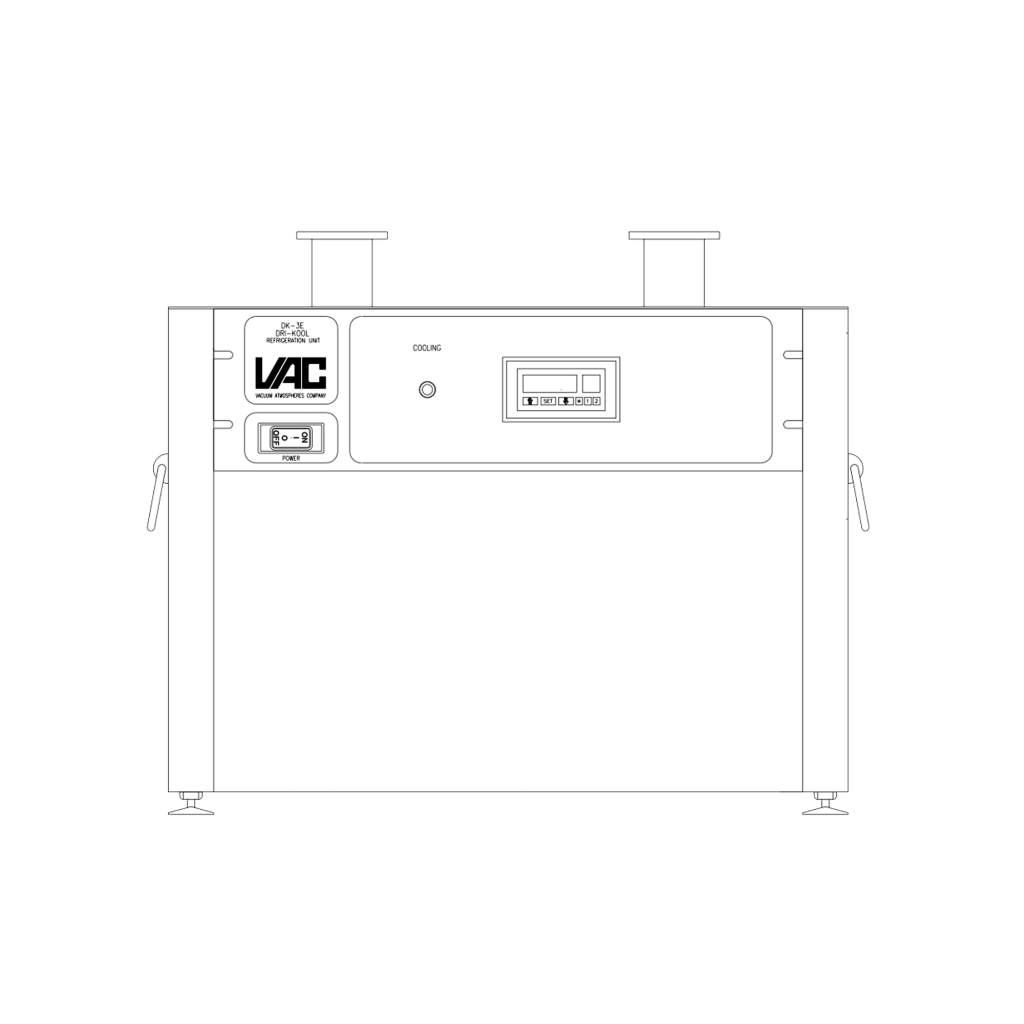

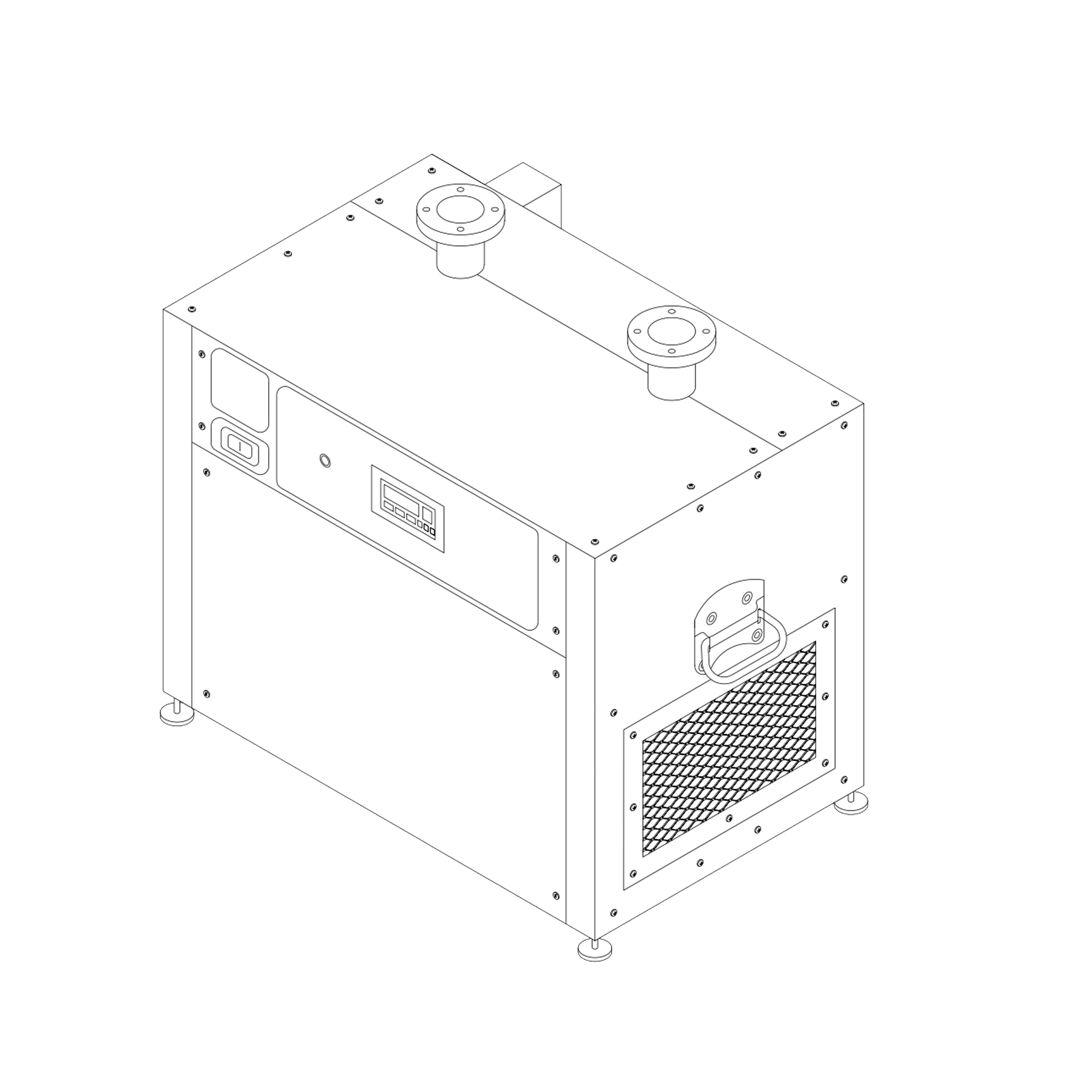

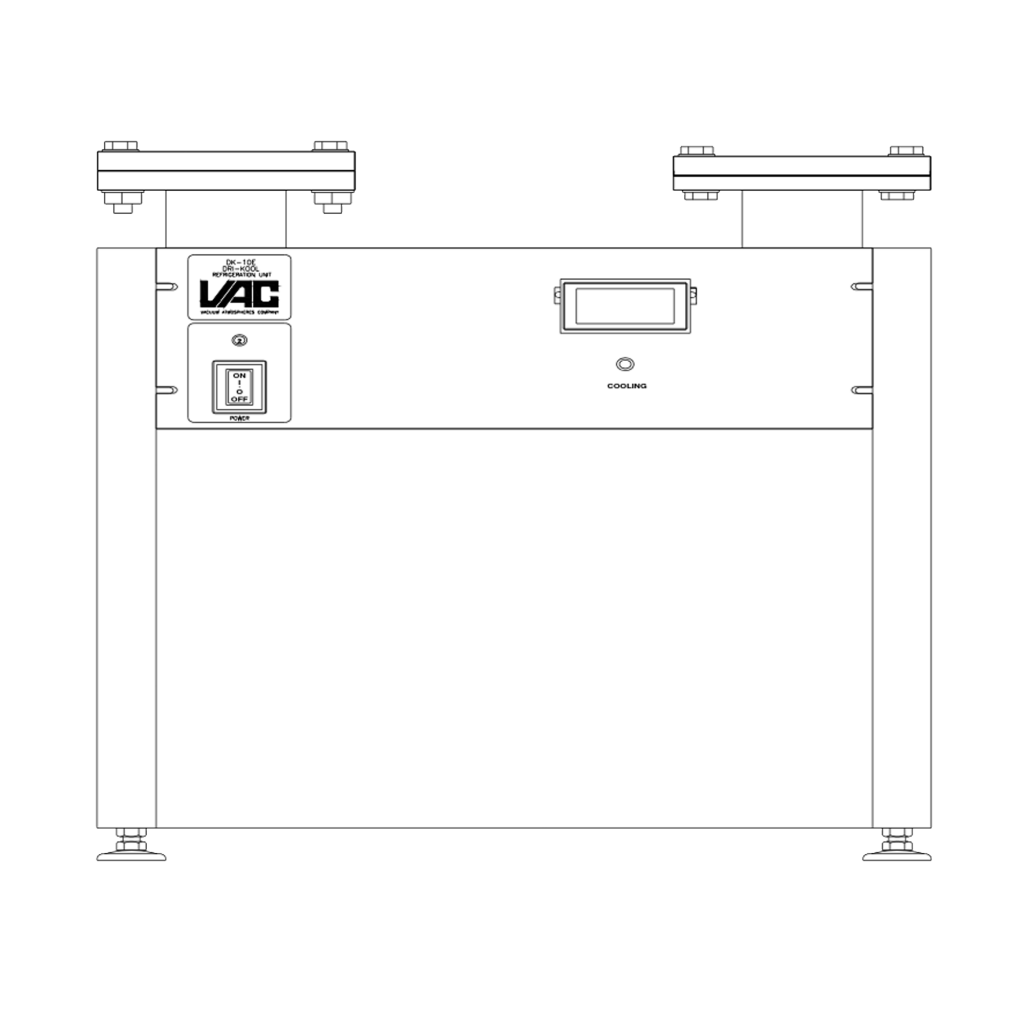

The major system components include an evaporator, air-cooled condensing unit, atmosphere circulation blower, and digital temperature controller. The internal (i) configuration is installed on the glovebox ceiling, with the evaporator and the circulation blower inside the glovebox.

The DK-3i is our most popular glovebox cooling platform and has been designed to operate with most VAC inert atmosphere glovebox systems.