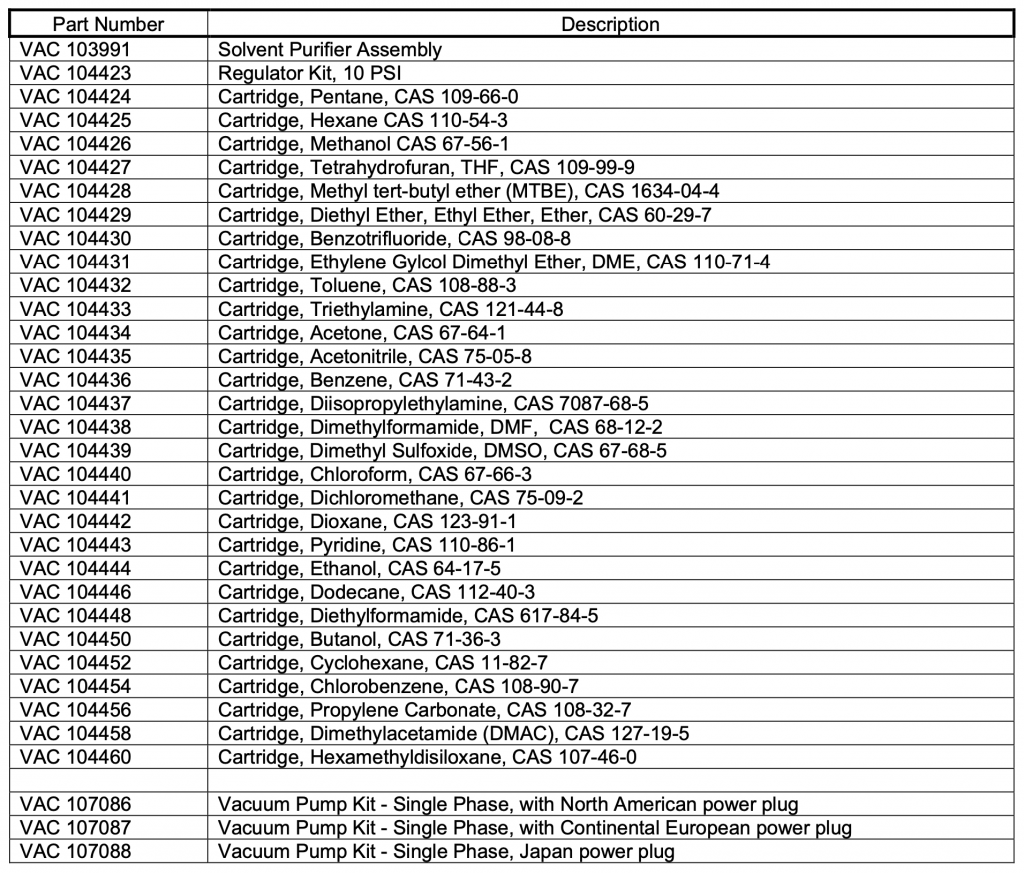

The Vacuum Atmospheres Patented Solvent Purifier System (SPS) is a safer method for drying organic solvents when compared to thermal distillation. The system repeatedly circulates solvent through a factory conditioned purification cartridge and a stainless steel reservoir.

The system is sized to be filled or refilled with a 4 liter solvent bottle. The compact size eliminates the need to store large quantities of volatile solvents and reduces potential waste of large amounts of solvent due to accumulation of impurities, such as peroxides. Most importantly this very safe drying method does not require heat or reactive drying agents.

The SPS allows for the dispensing of precise amounts of anhydrous solvents on demand.

Ask us about our in-box dispensing options.