VAC designs and fabricates a variety of custom gloveboxes/containments or custom versions of our standard commercial glovebox products. These custom systems may involve design to specification, engineering analysis, welding to ASME Code Section IX, certified welding inspections, certified leak check, and material and process certifications.

Custom Gloveboxes and Applications

Vacuum Atmospheres Company (VAC) is a supplier of turnkey systems. VAC has extensive experience developing and supplying complete custom systems for any application.

Process Integration

- Specification development

- System engineering and design to customer specifications

- State of the Art design with AutoCad and Solid Works

- Complete documentation for customer approval

- System integration to customer specifications

- Turnkey custom process systems

- Automation design and integration

Vacuum Deposition Glovebox Systems

Thin Film Deposition In Inert Atmosphere

- High Volume Turbo Pump

- Rotating Substrate Holder

- Shutter Control

- Dual 2 KVA Resistive Sources

- Optional Additional Sources

- Inficon XTN Rate Monitor

- Optional Cryogenic Pump

- Optional SST Chamber w/external access

Laminar flow inert glovebox system with integrated evaporator

- Rapid Particle Removal

- Class 10 or Better Cleanroom Environment

- Inert Atmosphere

- Variable Laminar Flow, 30 – 90 LFM

- 0.12 Micron HEPA FIlter, ULPA Filter Optional

- Dual Column Inert Gas Purifier

- Oxygen and Moisture Analyzers

- Optional Oil Free Vacuum Pump

Turnkey solutions for vacuum deposition, spin coating and device testing in an inert atmosphere.

- Unique base plate design provides for multiple sources configured in an arc at the front of the base plate, providing enhanced film uniformity combined with easy source loading and replacement.

- Stainless steel bell jar with viewport and sacrificial glass for easy clean-up of viewing area.

- Pneumatic bell jar lift raises bell jar following refill from low moisture glovebox atmosphere.

- Direct drive rotary work holder with adjustable height, tilt and rotation speed. Easy to view and reach platen allows for easy mask and substrate loading.

- 1-2% deposition uniformity across 4-5 inches.

- Pump stack with 300l/sec turbo pump backed with Edwards RV-8 12 CFM direct drive roughing pump. Vacuum pressure routinely reaches 5 X 10-6 Torr.

- Deposition rate and thickness monitor with slide out crystal drawer for easy crystal replacement.

- Integrated touch screen controls with built in diagnostics for all glovebox, bell jar and evaporation functions. Including automatic pump, vent and built in diagnostics

- Optional co-deposition functions available upon request

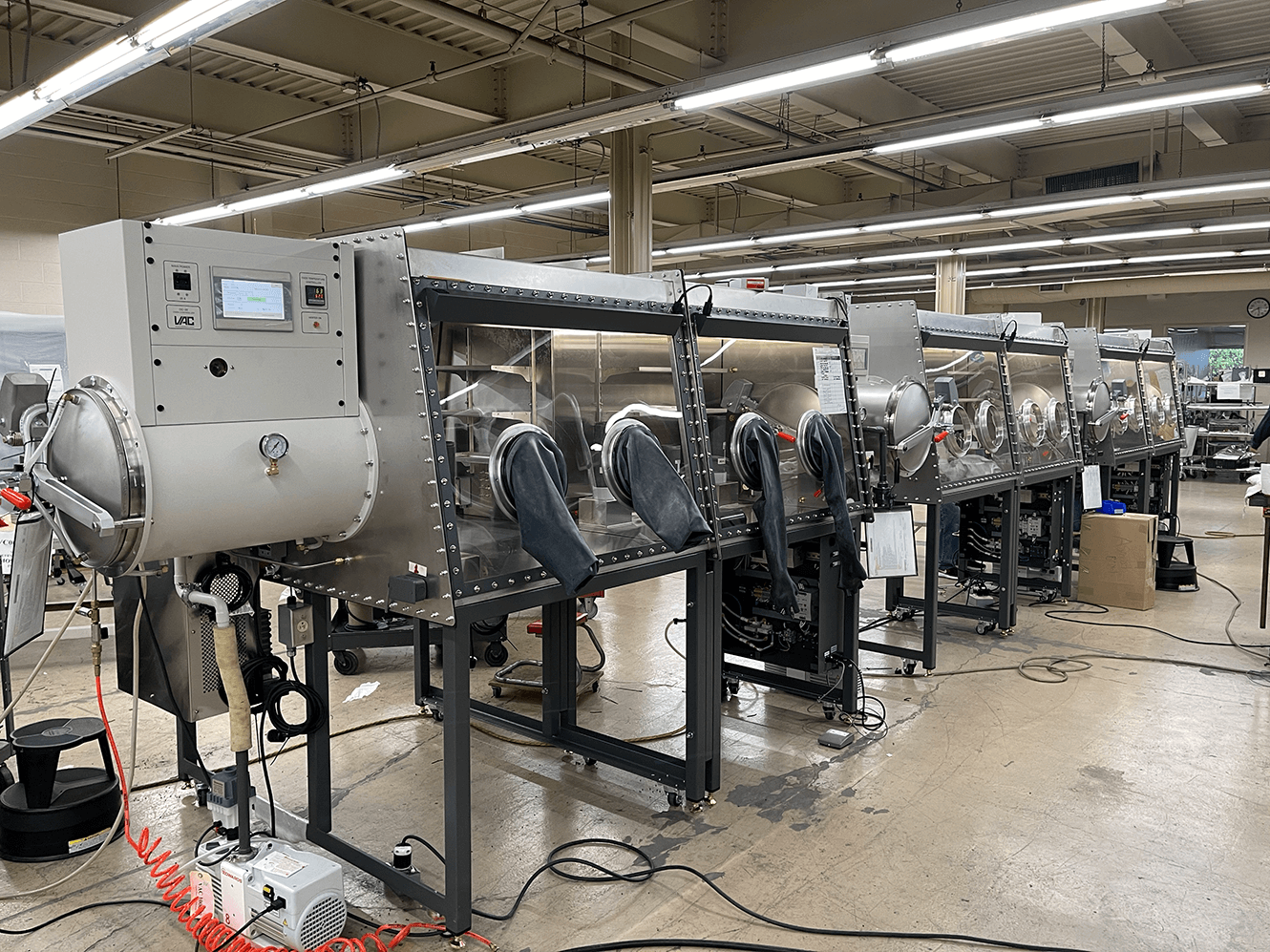

Battery Research

Complete turnkey battery research or production systems with gloveboxes

Vacuum Atmospheres Company can provide complete turnkey systems to meet any Battery Manufacturer’s requirement for a glovebox battery research/production system. Using this turnkey service, customers can be assured of complete and thorough integration of the equipment before shipment. This means minimal disruption to the customer’s facility and there is less administrative cost as the customer awards only a single contract.

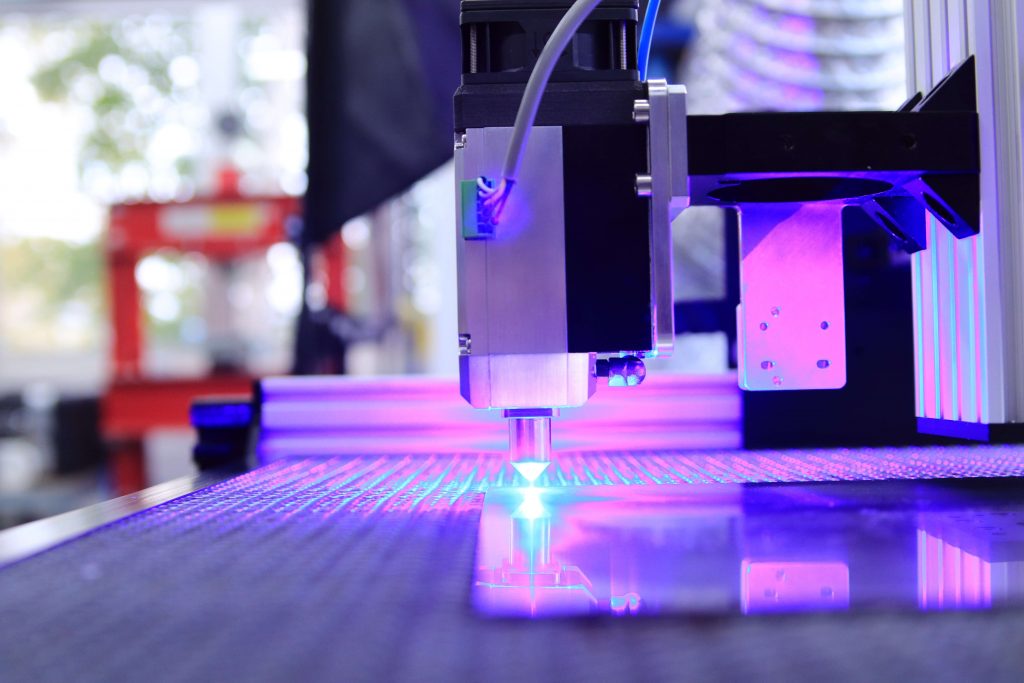

Laser Welding

Engineered For Laser Welding

- Complete System -Ready for Laser and Positioner

- Extended Work Station with Tooling Plate

- Vacuum Oven and Controller

- Particulate/Soot Removal System

- Power and Control Feedthrus for Positioner

- Illuminator for Machine Vision

- Electrical Load Center for Entire System

- Oil Free Scroll Pumps

- Oxygen and Moisture Monitors

Negative Pressure Glovebox

Designed for radiological applications

- Glovebox system may be easily configured to operate at negative pressure.

- Glovebox system may be easily configured to operate with negative pressure purge.

- Ideal application for VAC cartridge purification systems, as all purification occurs inside the glovebox.

- Saturated cartridges may be bagged out and replaced by VAC supplied, fully regenerated cartridges.

Nexgen Biotechnology Systems

Designed for Biotechnology applications

- Advanced Tissue Repair Research

- Tissue remodeling

- Tissue-repair products from biomaterials

- Biomaterial research

Fully Custom Gloveboxes

Our manufacturing abilities allow us to design and build custom glovebox solutions to match your exacting needs, whether you need a modified standard system with extra glove ports, or a fully custom design to accommodate heavy machinery with multiple access points.